Tire Production

Tire Production

How a tire is made

A tire is a complicated assembly of parts manufactured from various materials. So how are we supposed to get from the rubber tree to the road? Tire manufacturing is a multi-step process. Let's follow a Continental tire through all five phases of tire production:

Material sourcing and

compound manufacturing

- Manufacturing of components

- Building the tire

- Vulcanization

- Quality control

Stage 1: Quality ingredients to make essential compounds

Many industries offer raw materials to the tire manufacturing business, which are then utilized to generate the requisite compounds.

Steel Steel is produced by the steel industry. This is the beginning material for the production of steel belts (steel cord) and bead cores (steel wire).

Chemicals. The chemical industry is a key provider of tire ingredients. Synthetic rubber and materials, in particular, are utilized to minimize tire wear, enhance grip, and extend tire life.

Rubber from nature Rubber is collected from enormous plantations of specific plants. When acid is introduced to the milky fluid (latex), it coagulates. It is then washed and compressed into solid bales for better transport and storage.

Natural and synthetic rubber bales are sectioned, chopped into pieces, weighed, and blended with other substances according to exact formulae. In modern passenger automobile tires, up to twelve distinct rubber compositions are employed.

Textiles The textile sector provides raw materials (rayon, nylon, polyester, and aramid fibers) for the production of cords used as tire reinforcement.

Stage 2: Manufacturing of components

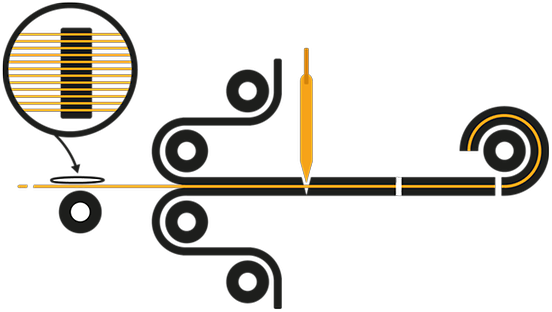

Steel wire Pre-treated steel cable on wire spools is inserted into a calendar and embedded in one or more layers of rubber. As a consequence, a continuous sheet of string and rubber is formed. This is cut at a set angle to the right tire size length and rolled up for further processing.

Tread The kneadable rubber material, which has been mixed in a mixer, is now ready to be formed into the tread. The rubber is formed into an infinite strip of tread using a screw-type extruder. The weight per meter is tested after extrusion, and the tread is cooled by immersion. The tread strip is trimmed to the appropriate length for the tire size. Following that, another unit weight control is performed.

Cord made of textiles A massive roller mechanism feeds a slew of textile threads into the calendar, which are then embedded in a thin layer of rubber. This unending sheet is then sliced to the necessary width and rewound for additional processing at a 90° angle to the direction of travel.

Bead made of steel The bead's core is made up of several ring-shaped steel wires. They each have their unique rubber covering. A rubber apex is then attached to this loop.

Sidewall The extruder produces sidewall portions that are trimmed to fit the specific tire size. Inner lining. The airtight inner lining is formed into a broad, thin layer by a calendar.

Stage 3: Building the tire

The tire construction may now commence. The different semi-finished components are integrated into what is known as a "green tire" on the tire assembly machine. This is accomplished in two stages: casing and tread/belt assembly. This "green tire" is then prepared for vulcanization by being sprayed with a specific fluid.

Stage 4: Vulcanization

We're now in the curing press. The tire is given its final shape after being vulcanized for a specific amount of time at a specific pressure and temperature. Raw rubber is transformed into flexible, elastic rubber throughout this procedure. The tread design and sidewall marks are etched on curing press molds.

Stage 5: Quality control

Each stage of manufacturing, from raw material inspection to completed tire delivery, is subject to continuing quality control.

Continental tires are extensively verified for quality using a multi-layered method. Continental finished tires are subjected to the following tests:

- Visual inspection

- X-raying

- Various tire uniformity checks

Tires are shipped to the distribution warehouse once they have passed all tests and inspections.

Copyright © 2024 Continental Middle East DMCC All rights reserved.